commercial director

Usage

Tires and rubber

Ceramics and glass

Food

Pharmaceuticals and cosmetics

Chemicals

Electronics

Coatings

Plastics

Solar energy

Products

Technological process

Melting, evaporation of zinc and oxidation of its vapors is carried out in muffle furnaces of continuous operation.

A muffle furnace is a chamber made of refractory bricks, in which muffles are arranged horizontally.The temperature in the furnace chamber varies between 1100-1450 0C

The zinc loaded into the muffle melts, heats up and evaporates intensively at a temperature of 870 C.

Zinc vapors from the muffle enter the oxidation well, where they are oxidized by air oxygen.

In the oxidation wells, with the help of mill fans installed between the furnaces and the filter equipment, the discharge is maintained. The oxidation reaction of zinc vapor proceeds exothermically.

Team

Commercial Director of KTIAM Management Company

purchasing manager

market leaders

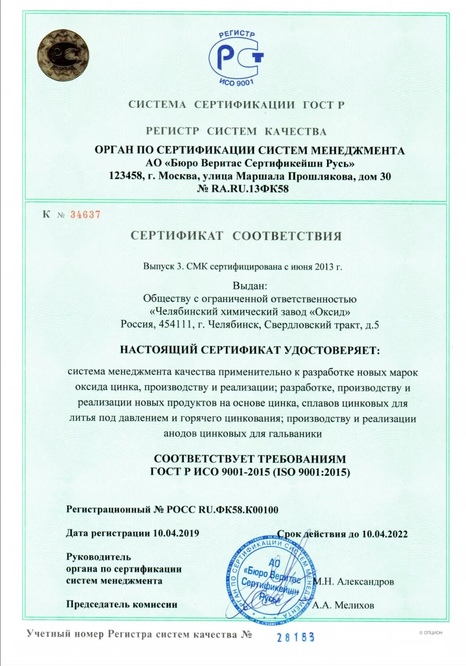

About company

Zinc oxide is widely used in the manufacture of tires, in the rubber and chemical industries.

- As part of toothpastes and cements for dentistry

- In cosmetic sun creams and cosmetic procedures

- Fillers, artificial leather and rubber products

- In the oil refining industry

Request

News